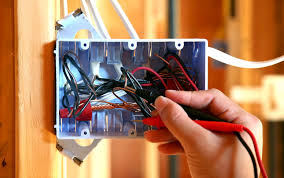

How to Size a Junction Box Correctly

Correctly sizing a junction box is a critical part of any safe and compliant electrical installation. Whether you are working on residential wiring, commercial electrical systems, or industrial projects, using the right junction box size helps prevent overheating, protects wire connections, and ensures your setup meets electrical codes. Many installers and sourcing professionals rely on trusted technical resources like lianjer to understand proper sizing principles and avoid costly mistakes.

This in-depth guide explains how to size a junction box correctly, covering code requirements, wire calculations, common errors, and best practices. The goal is to help electricians, contractors, engineers, and sourcing professionals make informed decisions with confidence.

What Is a Junction Box and Why Size Matters

A junction box is an enclosure that houses electrical wire connections, protecting them from damage and reducing fire risks. It also keeps connections accessible for inspection, maintenance, and future upgrades.

Why Proper Junction Box Sizing Is Important

Prevents overheating caused by overcrowded wires

Reduces fire and electrical hazards

Ensures compliance with electrical codes

Protects wire insulation from damage

Makes future maintenance easie

Using a box that is too small can lead to serious safety issues, while an oversized box may be inefficient or unnecessary.

Understanding Electrical Box Fill Rules

Electrical box sizing is governed by box fill rules, which define how many conductors and components can safely fit inside a junction box. These rules are outlined in major electrical standards such as the National Electrical Code (NEC).

What Box Fill Means

Box fill refers to the maximum number of wires, devices, and fittings allowed inside a junction box. Each component takes up a specific amount of volume.

Exceeding box fill limits can cause:

Excessive heat buildup

Damaged insulation

Loose or unsafe connections

Understanding these limits is the foundation of correct junction box sizing.

Standard Wire Volume Allowances

Each wire inside a junction box is assigned a volume based on its gauge. Thicker wires require more space.

Common Wire Volume Values

14 AWG wire: 2.0 cubic inches

12 AWG wire: 2.25 cubic inches

10 AWG wire: 2.5 cubic inches

Only current-carrying conductors are counted. Ground wires are usually counted as a single conductor, regardless of quantity.

How to Calculate Junction Box Size Step by Step

Sizing a junction box involves a simple calculation when done correctly.

Step 1: Count Conductors

Count all insulated wires entering the box. Each wire counts as one conductor.

Step 2: Add Grounds

All ground wires together count as one conductor based on the largest ground wire size.

Step 3: Include Devices and Clamps

Each internal clamp counts as one conductor

Devices like switches or outlets count as two conductors

Step 4: Multiply by Wire Volume

Multiply the total conductor count by the volume allowance for the wire gauge used.

Step 5: Choose a Box With Adequate Volume

Select a junction box with a cubic inch capacity equal to or greater than your calculated requirement.

Common Junction Box Sizes and Applications

Junction boxes come in various shapes and sizes, each designed for specific applications.

Popular Junction Box Types

Single-gang boxes – Used for switches or outlets

Double-gang boxes – For multiple devices

Square boxes – Ideal for multiple wire connections

Round boxes – Common for lighting fixtures

Octagon boxes – Used for ceiling fixtures and fans

Each type has a different volume rating, so checking manufacturer specifications is essential.

Indoor vs Outdoor Junction Box Considerations

The environment where a junction box is installed also affects sizing and selection.

Indoor Junction Boxes

Usually plastic or metal

Focus on wire volume and accessibility

Must remain accessible after installation

Outdoor Junction Boxes

Require weatherproof and corrosion-resistant materials

Often need extra space for seals and fittings

Must be rated for moisture and dust exposure

Outdoor installations may require larger boxes to accommodate protective components.

Material Choice and Its Impact on Sizing

Junction boxes are commonly made from plastic or metal, and each material has advantages.

Plastic Junction Boxes

Lightweight and easy to install

Non-conductive

Often have built-in clamps

Metal Junction Boxes

Stronger and more durable

Required in some commercial or industrial settings

Must be properly grounded

Material choice does not change box fill rules, but it can influence installation methods and compliance requirements.

Common Mistakes When Sizing Junction Boxes

Even experienced professionals sometimes make errors.

Mistakes to Avoid

Ignoring internal clamps in calculations

Forgetting to count devices

Using wire gauge assumptions instead of actual sizes

Overfilling boxes to save space

Using non-compliant or uncertified boxes

Avoiding these mistakes improves safety and long-term reliability.

Junction Box Sizing for Different Projects

Different projects have different requirements.

Residential Installations

Often use 14 or 12 AWG wires

Smaller boxes are common

Must follow strict safety standards

Commercial Installations

Larger wire gauges

Higher conductor counts

Metal boxes are frequently required

Industrial Applications

Heavy-duty enclosures

Specialized fittings

Higher heat and load considerations

Understanding project scope helps determine the correct box size.

Compliance With Electrical Codes and Standards

Electrical codes exist to protect people and property. Failing to comply can result in failed inspections, fines, or safety hazards.

Why Code Compliance Matters

Ensures installation safety

Prevents legal issues

Protects equipment and property

Improves long-term reliability

Always follow local and international electrical regulations applicable to your project.

Choosing the Right Junction Box Supplier

Quality matters just as much as correct sizing. Poor-quality boxes may crack, deform, or fail under stress.

When sourcing junction boxes, many professionals consult detailed guides such as Size junction box resources to ensure they select the right enclosure for their wiring needs. Reliable suppliers provide accurate specifications, certified products, and clear technical documentation.

Best Practices for Safe Junction Box Installation

Correct sizing works best when paired with proper installation.

Installation Tips

Do not force wires into the box

Secure all wire connections properly

Use approved connectors

Keep boxes accessible

Label circuits when possible

These practices enhance safety and simplify future maintenance.

How Proper Sizing Improves Long-Term Performance

Correctly sized junction boxes reduce the likelihood of:

Overheating and fire risks

Insulation damage

Loose or stressed connections

Costly repairs or rework

Proper planning saves time, money, and ensures system reliability.

Final Thoughts

Understanding how to size a junction box correctly is essential for safe, efficient, and code-compliant electrical installations. From calculating wire volume to choosing the right box type and material, every step plays a role in long-term performance and safety.

By following established standards, avoiding common mistakes, and using trusted technical references like lianjer, professionals can ensure their electrical projects meet both safety and quality expectations. Taking the time to size junction boxes correctly today helps prevent serious problems tomorrow and supports reliable electrical systems across residential, commercial, and industrial environments.

Disclaimer

The information provided in this article, “How to Size a Junction Box Correctly,” is intended for general educational and informational purposes only. While every effort has been made to ensure accuracy and alignment with commonly accepted electrical standards and practices, this content should not be considered a substitute for professional electrical advice, on-site inspection, or compliance verification.

Electrical codes, including National Electrical Code (NEC) requirements and local regulations, may vary by location and are subject to change. Always consult a licensed electrician, electrical engineer, or local building authority before performing or approving any electrical work. Improper installation, incorrect sizing, or failure to follow applicable codes can result in serious safety hazards, property damage, or legal liability.