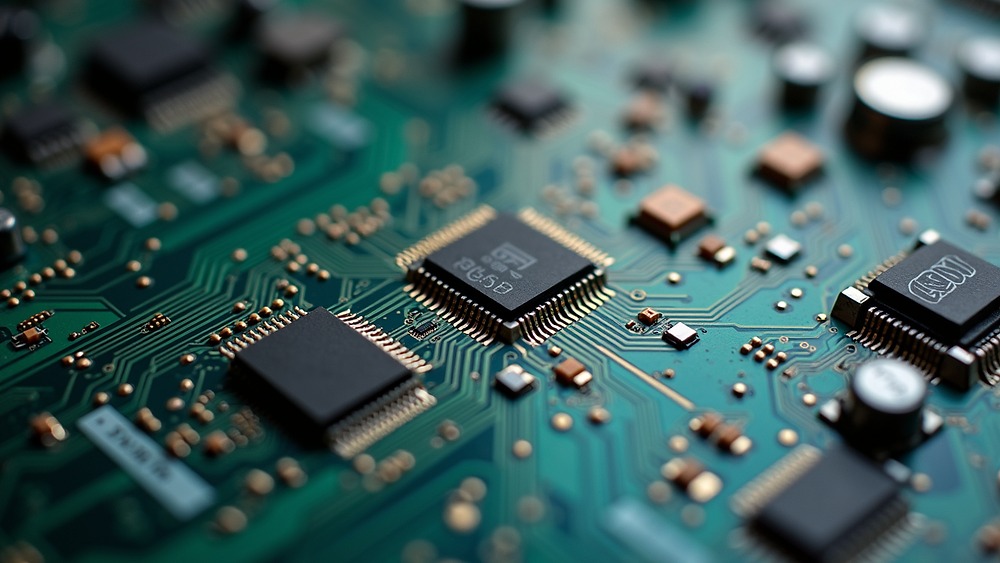

How to Choose Advanced PCB Solutions for Modern Electronics

In today’s fast-paced electronics industry, selecting the right PCB technology is essential for building efficient, reliable, high-performance devices. Engineers working on robotics, telecommunications, automotive electronics, or power systems increasingly rely on advanced PCB types such as rigid-flex PCBs, high-frequency boards, and metal-core solutions to meet demanding requirements. When sourcing these technologies, many professionals begin by evaluating a Metal core PCB supplier, especially those known for advanced engineering and quality fabrication standards, such as resources found on These solutions continue to transform how modern devices are designed, cooled, powered, and assembled.

As electronic systems become smaller, more powerful, and more thermally demanding, traditional FR-4 boards rarely meet all project needs. Manufacturers in sectors like automotive control systems, drones, renewable energy equipment, and medical devices demand better thermal stability, mechanical flexibility, and clean signal transmission. That’s why rigid-flex PCBs, MCPCBs, and high-frequency boards have become mainstream for engineers who need performance far beyond standard materials.

Why Advanced PCB Technology Matters Today

The evolution of PCB technology has been driven by the increasing need for efficiency, stability, and durability. Traditional PCBs have limitations that can restrict design flexibility and long-term performance:

Thermal Stress & Heat Management Challenges

High-power LEDs, motor controllers, RF amplifiers, and voltage regulators generate significant heat. Standard FR-4 materials have limited thermal conductivity, leading to:

- Component overheating

- Shortened lifespan

- Decreased device efficiency

- Higher failure rates

Metal-core PCBs address this by integrating aluminum or copper substrates that rapidly pull heat away from critical components.

Space Constraints & Mechanical Complexity

IoT devices, wearables, drones, and medical tools increasingly require flexible forms. Rigid boards alone cannot conform to curved shapes or dynamic movement. Rigid-flex PCBs solve this by combining flexible dielectric materials with rigid sections for components, enabling tightly packed 3D architectures.

High-Speed & High-Frequency Signal Integrity

Telecommunications, radar, automotive sensing, and 5G equipment rely on accurate RF transmission. Standard materials introduce:

- Signal attenuation

- Impedance instability

- Electromagnetic interference (EMI)

High-frequency PCB materials, like PTFE or Rogers laminates, ensure consistent performance at GHz-level speeds.

Durability & Harsh Environment Requirements

Industrial automation, robotics, aerospace, and automotive devices require PCBs that endure:

- Vibration

- Temperature cycling

- Chemical exposure

- UV and humidity

- Constant mechanical movement

Advanced PCBs are engineered to withstand these conditions better than standard FR-4.

Understanding Rigid-Flex PCBs

Rigid-flex PCBs combine the structural strength of rigid boards with the bending capability of flexible circuits. They are essential in compact or rugged environments.

Key Advantages

- Reduced connectors & solder joints → fewer failure points

- 3D architecture → better use of internal space

- Lower weight and volume compared to multi-board cable systems

- Excellent reliability under vibration → perfect for drones and robots

- Improved signal integrity due to shorter interconnect paths

Common Applications

- Wearables & fitness trackers

- Aerospace controls

- Robotic joints and actuators

- Portable medical devices

- High-density consumer electronics

Rigid-flex PCBs also help simplify final assembly by eliminating connectors and ribbon cables, making production faster and cleaner.

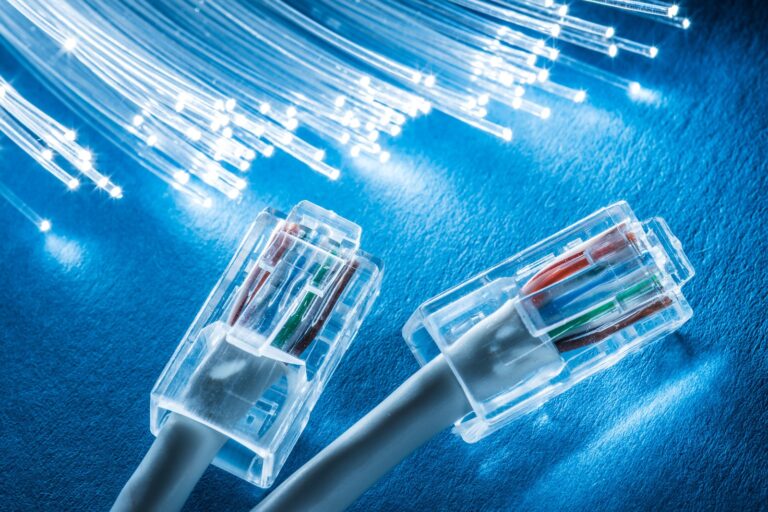

High-Frequency PCB Capabilities

High-frequency PCBs are essential wherever fast signals must travel with minimal interference. These boards use specialized dielectric materials with consistent electrical properties.

Benefits of High-Frequency PCBs

- Stable impedance for sensitive RF circuits

- Reduced signal loss during high-speed transitions

- Better EMI/EMC performance

- Suitable for 5G, radar, satellite, and IoT systems

- These boards are often built with materials like:

- PTFE laminates

- Rogers 4350/4003 series

- Low-loss hydrocarbon ceramics

- Advanced epoxy resins

Industries Relying on High-Frequency PCBs

- Telecommunications (routers, antennas, repeaters)

- Automotive radar (ADAS systems)

- Aerospace navigation

- High-speed computing

- Test and measurement equipment

- In all these applications, accuracy and clean signal transmission are essential.

Metal-Core PCBs for High Power & Heat Dissipation

Metal-Core PCBs (MCPCBs) are engineered for excellent thermal management. They typically include:

- A metal substrate (aluminum or copper)

- Thermally conductive dielectric layer

- Copper circuit layer

- This configuration dramatically improves heat transfer compared to FR-4.

Key Advantages

- Excellent thermal conductivity

- Lower junction temperatures for LEDs and power devices

- Increased mechanical stiffness

- Better long-term reliabilit

- Higher current handling

Typical MCPCB Applications

- LED lighting modules

- Power drivers

- Motor control units

- Electric vehicles

- Solar inverters

- High-current industrial electronics

MCPCBs remain the go-to option for any design where heat must be managed efficiently without expensive external cooling.

Industries Benefiting from Advanced PCB Solutions

1. Telecommunications & 5G

High-frequency PCBs ensure stable RF transmission for:

- Base stations

- Remote radio units

- Microwave links

- Antenna arrays

- Rigid-flex PCBs also help reduce weight and size in telecom equipment.

2. Robotics & Automation

Robotics relies heavily on advanced PCBs due to:

- Constant vibration

- Mechanical movement

- Tight space restrictions

- Rigid-flex enables electronics to be placed inside arms, joints, and rotating systems.

3. Automotive & EV Systems

Metal-core PCBs are widely used in:

- Battery management systems

- Power controllers

- LED headlights

- Charging modules

- Automotive environments require superior heat dissipation and durability.

4. Medical Electronics

Medical devices need precision, stability, and compact designs:

- Diagnostic tools

- Wearable sensors

- Surgical instruments

- Rigid-flex PCBs provide the reliability and space optimization these applications demand.

5. Aerospace & Defense

Aerospace systems require light weight, thermal stability, and vibration resistance:

- Communication modules

- Radar electronics

- Navigation systems

- Advanced PCB technologies excel in these demanding conditions.

How to Choose the Right PCB Manufacturer

When searching for a manufacturer capable of supporting advanced PCB solutions, consider these critical factors:

1. Manufacturing Expertise

Look for capabilities such as:

- Rigid-flex fabrication

- Aluminum and copper MCPCB production

- High-frequency material handling

- Controlled impedance testing

- Blind, buried, and micro-vias

2. Quality Control & Certifications

A reliable manufacturer will have:

- ISO and IPC certifications

- AOI and X-ray inspection

- Thermal cycling tests

- Electrical testing

- Strict material traceability

3. Engineering Support

A strong PCB supplier should offer:

- DFM analysis

- Stack-up recommendations

- Material selection guidance

- Early collaboration with designers

- This reduces risks during mass production and improves final output.

4. Prototyping and Volume Flexibility

Choose suppliers who support:

- Rapid prototype

- Small batch production

- High-volume runs

- This ensures scalable manufacturing for both startups and large enterprises.

Best Design Practices for Advanced PCBs

1. Choose the Right Materials Early

Thermal demands, frequency requirements, and mechanical flexibility should guide your laminate selection.

2. Plan for Controlled Impedance

Work closely with your manufacturer to define:

- Trace width

- Dielectric spacing

- Layer stack-up

- Grounding strategy

3. Optimize Thermal Management

For MCPCBs:

- Add thermal vias

- Use heat spreaders

- Position heat-generating components carefully

4. Design Flex Sections Properly

For rigid-flex PCBs:

- Avoid components on flex layers

- Follow bend radius guidelines

- Keep traces perpendicular to bends

5. Consider Testing Requirements

RF and power systems often require:

- Impedance testing

- EMI/EMC evaluation

- Thermal cycling

- Functional testing under load

Final Thoughts: Building Better Electronics with Advanced PCB Solutions

As electronics become more compact, powerful, and thermally demanding, advanced PCB technologies like rigid-flex, high-frequency, and metal-core PCBs are essential for achieving reliability, efficiency, and long-term stability. Engineers building robotics, telecom equipment, LED modules, automotive power systems, or medical devices must focus on PCB materials and design from the earliest stages of development.

Selecting the right supplier ensures your board performs correctly under real-world conditions—heat, vibration, high-speed signals, or continuous mechanical flexing. For teams looking for trusted resources, globalwellpcba.com offers in-depth guides, manufacturing insights, and advanced PCB solutions that support demanding industries worldwide, helping engineers bring next-generation electronics to market with confidence.